+86 13777722188

+86 13777722188

In today's electrical projects, choosing the right Control Cable is crucial. According to a recent report by the International Electrotechnical Commission, the global control cable market is projected to grow significantly. This indicates a rising demand for high-quality control solutions. Experts emphasize the importance of selection in achieving optimal performance.

One industry expert, John Smith, stated, "The right Control Cable ensures safety and efficiency in electrical systems." A variety of factors influence this choice, including cable type, construction materials, and application environments. Understanding these elements can seem overwhelming. Many engineers face challenges in identifying the most suitable options.

A common mistake is overlooking the specific requirements of a project. The wrong Control Cable can lead to malfunctions or safety hazards. Careful consideration and research are essential in navigating this complex landscape. Making informed decisions will enhance project success and minimize risks.

When it comes to control cables, understanding the types available is crucial. Different projects require specific cable types. The right choice impacts performance and safety. Control cables generally fall into categories based on their construction and application. For instance, two common types are shielded and unshielded cables.

Shielded cables offer protection against electromagnetic interference. They work well in noisy environments.

Unshielded cables are less expensive but come with risks. They may not perform well in areas with electrical disturbances.

Another aspect to consider is the cable's flexibility. Some projects require cables that can bend easily without breaking. This is especially important in tight spaces or complex installations. Additionally, pay attention to the voltage rating. Using a cable with an insufficient rating can lead to failures or safety hazards.

It is essential to evaluate your specific needs before making a decision. Often, the best choice is not immediately clear. Rushing this step can cause issues later on. You might find yourself redoing work or facing unexpected costs. Take the time to analyze the environment and requirements. Be mindful and choose wisely.

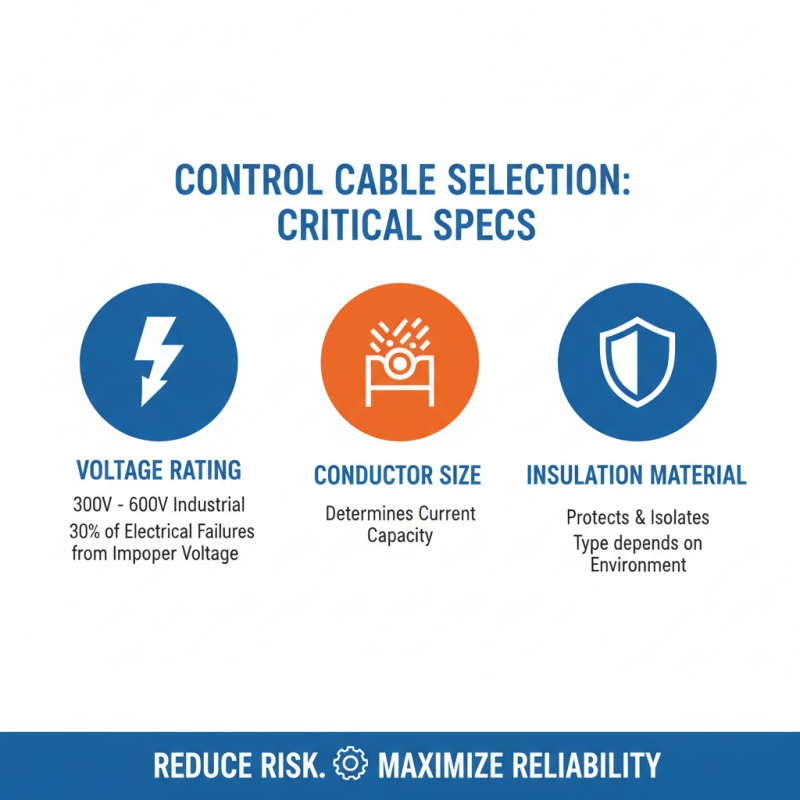

When selecting a control cable, understanding key specifications is essential. The most critical factors include voltage rating, conductor size, and insulation material. Voltage ratings typically range from 300V to 600V for most industrial applications. Reports indicate that improper voltage ratings contribute to 30% of electrical failures. That’s a substantial risk for your projects.

Conductor size is another significant aspect. A larger cross-sectional area can reduce resistance and heat generation. Data shows that using undersized conductors can lead to overheating, increasing the likelihood of failures. Moreover, insulation materials greatly impact a cable's durability. PVC, for example, is common but may not perform well in extreme temperatures. In contrast, rubber or silicone variations offer better flexibility and resilience.

Another detail to consider is environmental factors. Cables exposed to moisture need specific ratings to avoid short circuits. Industry studies reveal that moisture-related failures account for 20% of electrical issues in outdoor setups. Choosing the right specifications helps in optimizing performance and reliability. Failing to do so could lead to costly downtime. So, take the time to evaluate your options carefully. It’s not just about compliance; it's about ensuring safety and efficiency.

When selecting the right control cable for your electrical projects, environmental factors play a crucial role. Temperature, moisture, and chemical exposure can significantly affect cable performance. Cables used in outdoor settings need extra protection against extreme weather. In contrast, indoor cables may be exposed to different challenges, such as dust and humidity.

Tip: Consider the temperature range in your project area.

Cables need to perform well at both high and low temperatures. Ensure the selected cable can withstand these variations.

Moisture can shorten cable life. Areas prone to flooding or condensation require cables with superior insulation. Chemical exposure can also damage cables, particularly in industrial settings. It’s important to assess whether your installation site may have any harsh chemicals present.

Tip: If you’re unsure, consult experts on material compatibility.

They can guide you on the best cable type for your specific environment. Remember, investing in the right cable can save you headaches down the line.

When choosing control cables for electrical projects, budget is a significant aspect. Every project has financial limitations. Evaluating cost-effectiveness is crucial. You want to buy cables that fit the project needs without overspending. Think about the long-term benefits. Sometimes, spending more initially can save money later on.

Many people focus solely on the upfront cost. This can lead to poor choices. In the end, low-cost cables could fail sooner, requiring replacements. Consider the materials used. Durable cables may have a higher price tag but generally last longer.

Analyze how many cables you need and their specifications. Comparing prices across different suppliers can help identify competitive rates. Look for bulk discounts, if possible. Keep in mind that cheaper options might compromise quality. It’s important to balance cost and performance. This is where evaluation becomes subjective, and choices can lead to regrets later. Think carefully before making a decision.

When selecting control cables for electrical projects, adhering to industry standards is vital. Standards like IEC 60228 outline requirements for conductors, ensuring safety and performance. According to a 2021 report by the International Electrotechnical Commission, compliance can significantly reduce hazards related to electrical failures. Missing these standards may lead to accidents, costly repairs, and project delays.

It’s crucial to consider the environment where the cables will be installed. For instance, harsh conditions like extreme temperatures or exposure to chemicals can affect cable performance. A study from the National Fire Protection Association highlighted that poorly selected cables contributed to 30% of electrical fires in industrial settings. This statistic is a wake-up call for engineers and project managers to carefully evaluate cable ratings and insulation types.

Moreover, regulatory bodies frequently update standards to address new technologies and safety concerns. This means continuous education is necessary. Professionals must keep track of changes in regulatory requirements to ensure ongoing compliance. Neglecting this could lead to outdated practices, risking both safety and financial stability in projects. Remember, informed choices have lasting impacts.

| Cable Type | Application | Temperature Rating | Voltage Rating | Compliance Standards |

|---|---|---|---|---|

| PVC Control Cable | General Control Systems | -20°C to +70°C | 450/750V | IEC 60227 |

| XLPE Control Cable | Heavy Machinery | -40°C to +90°C | 0.6/1kV | BS 7870 |

| LAPP Control Cable | Automation Systems | -5°C to +60°C | 300/500V | VDE 0281 |

| Fiber Optic Control Cable | Data Transmission | -40°C to +70°C | N/A | ANSI/TIA-568 |