+86 13777722188

+86 13777722188

Choosing the right electrical cable is crucial for any project. Electrical cables come in various types and sizes, each suited for different applications. Understanding your needs is essential to make an informed decision.

When selecting an electrical cable, consider factors such as voltage, current rating, and environmental conditions. For instance, a cable meant for outdoor use might need extra protection against moisture. Some cables are better suited for high temperatures, while others excel in flexible applications.

It can be overwhelming to navigate the options. Many people make the choice based on price alone, which might not be the best approach. Reflecting on specific requirements often leads to better long-term outcomes. Ultimately, the right electrical cable will enhance safety and efficiency in your project.

When choosing electrical cables, understanding the types available is crucial. The market offers various options, each serving specific purposes. For instance, there are copper and aluminum cables. Copper cables are renowned for their superior conductivity, making them ideal for high-demand applications. However, they are often more expensive. On the other hand, aluminum cables are lighter and more cost-effective, yet they may not handle high loads as efficiently.

Another key type is the armored cable. This cable type is designed for applications requiring additional protection from physical damage. In industrial settings, armored cables are preferred due to their durability. Meanwhile, flexible cables are essential for mobile equipment and machinery. These cables allow movement without compromising safety, yet they might wear out faster than their more rigid counterparts.

The global electrical cable market is projected to grow, reaching USD 250.6 billion by 2026, according to industry reports. This growth indicates a rising demand for diverse cable types. It is important to assess not only the specifications but also the intended application. Choosing the wrong type can lead to inefficiencies. So, careful consideration is necessary.

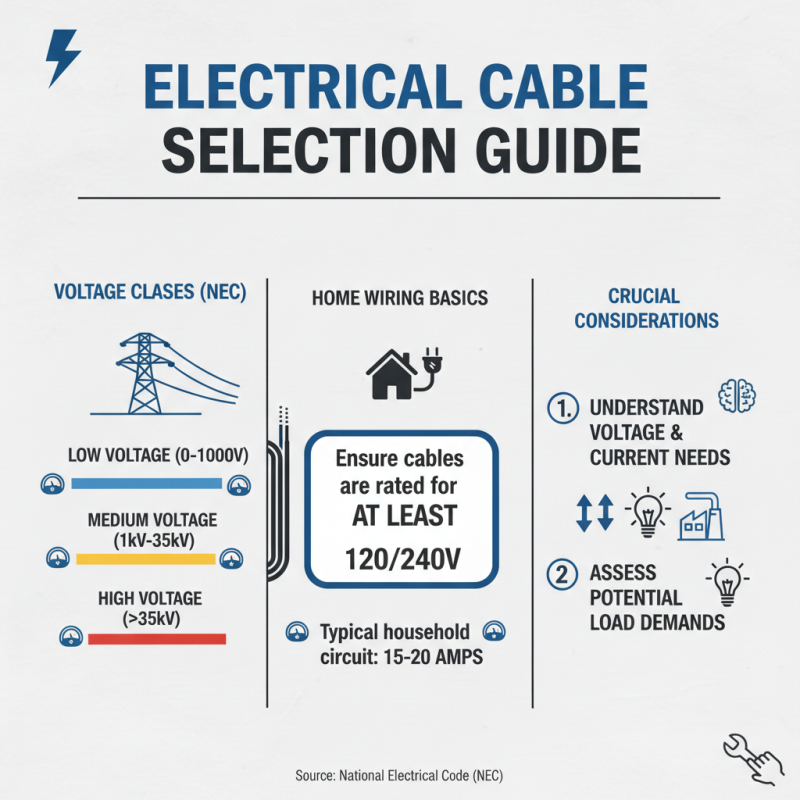

When selecting electrical cables, understanding voltage and current requirements is crucial. The National Electrical Code (NEC) defines voltage classes: low (up to 1,000V), medium (1,000V to 35kV), and high (above 35kV). For home wiring, ensure usage of cables rated for at least 120/240V. Always assess potential load demands. A typical household circuit may handle 15 to 20 amps.

Current capacity varies based on wire gauge. According to the American Wire Gauge (AWG) standard, a 12 AWG wire can safely carry about 20 amps. Conversely, a 14 AWG wire is limited to 15 amps. Overloading these can cause overheating. Consult local building codes and safety standards in your area.

Tips: Always round up your current assessment. If unsure, choose a larger gauge. It’s better to over-specify than to risk safety. Also, consider the length of the cable; longer runs may require larger cables to reduce voltage drop.

Evaluating your needs isn't just about numbers. Reflect on past experiences where improper cable selection led to issues. Learning from these can guide better decisions now. Remember, safety first!

When selecting electrical cables, insulation materials play a crucial role in performance. Different types of insulation materials offer distinct advantages and drawbacks. Thermoplastic, for instance, is common in many applications. It is flexible and resistant to moisture. However, it may not withstand high temperatures well. On the other hand, thermosetting materials provide better heat resistance. Yet, they can be more challenging to work with during installation.

The choice of insulation can affect safety and efficiency. Poor insulation may lead to energy loss. It could also pose fire hazards. Evaluating the environment where the cable will be used is essential. For example, if cables will be exposed to chemicals, specific materials are more suitable. Moreover, the thickness and type of insulation impact long-term durability. Inadequate thickness might lead to premature failures.

Installing the right cable is not just about choosing materials. It’s also about understanding how they interact with the electrical load. Not every scenario requires the same insulation. Sometimes, opting for a cheaper option can lead to regret. Reflecting on these factors can save time, money, and potential safety issues. Understanding insulation properties may seem tedious but is vital for lasting performance.

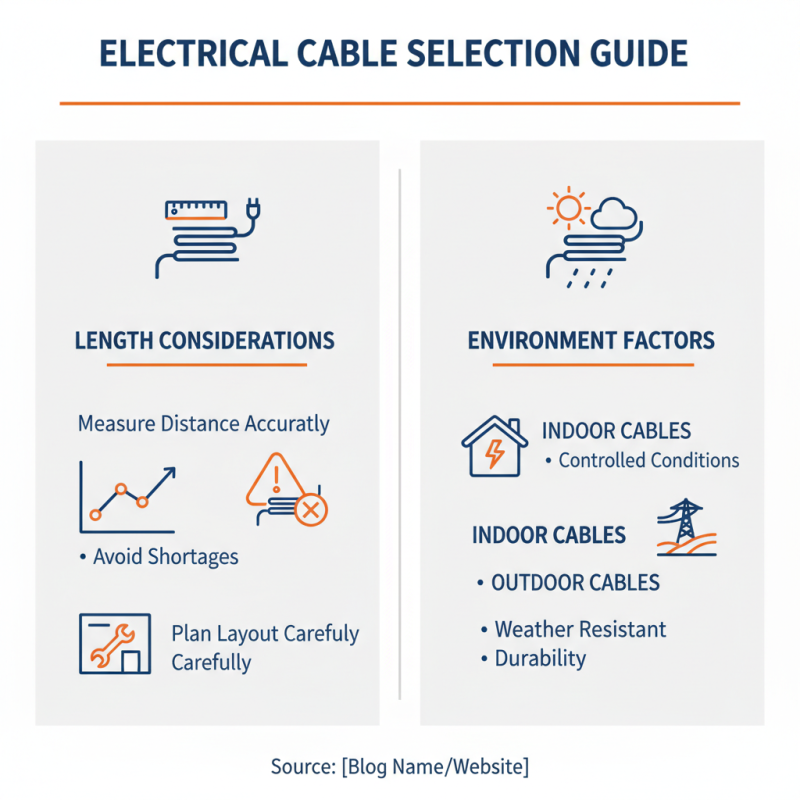

When choosing electrical cables, the length and installation environment are crucial. Measure the distance accurately before purchasing. A cable too short can lead to problems. It's essential to consider the layout of your space. A clear plan helps avoid miscalculations. The environment also influences your choice. Indoor cables are different from outdoor cables. They must endure various conditions.

Temperature, humidity, and exposure to elements matter. For example, if you're installing cables outside, they need extra protection. UV-rated cables resist sunlight better. In contrast, indoor cables often prioritize flexibility. They must navigate through walls and corners. Don't overlook factors like insulation and shielding.

You might be tempted to buy cheaper options. This could save money initially. However, it might lead to future costs. Inferior cables can malfunction or cause hazards. Always think about longevity and safety. It's a common mistake to underestimate these factors. Focus on your specific needs. A well-thought-out choice pays off in the long run.

When selecting electrical cables for specific applications, safety is paramount. Different environments require different cable types. For instance, cables in outdoor settings must withstand UV exposure and temperature fluctuations. According to the National Electrical Manufacturers Association (NEMA), around 25% of electrical fires originate from improper cable usage. This highlights the need for choosing the correct cables.

In industrial settings, cables should meet specific standards such as the NEC. Low voltage cables are common in commercial buildings. Yet, their improper installation can lead to overheating. Research shows that over 30% of workplace accidents are linked to electrical issues. Utilizing cables rated for higher ampacity can mitigate risks during peak loads.

Also, consider insulation types. PVC insulation is prevalent, but it may not perform well in extreme temperatures. On the other hand, XLPE offers better thermal resistance, but costs more. Investing in the right cables can impact safety. However, many still overlook this crucial aspect. They often prioritize cost over quality, potentially leading to serious consequences. Always consult with electrical professionals to make informed choices.