+86 13777722188

+86 13777722188

Installing Concentric Cable effectively is essential for ensuring reliability in electrical projects. This special type of cable offers advantages in power distribution. Its unique design allows for efficient transmission and minimized interference.

When you start planning your installation, consider various factors. High-quality tools and materials are crucial. Rushing through steps can lead to mistakes. Make notes of your measurements, as inaccuracies may lead to significant issues later.

Each project has its own challenges. Sometimes, environmental factors can complicate installations. Proper planning helps mitigate these risks. Learning from past experiences, whether yours or others’, can guide your approach to working with Concentric Cable. Always remain open to feedback, as it can enhance your technique.

Concentric cable is gaining traction in electrical projects. Its unique design consists of a central conductor surrounded by layers of insulation and outer conductors. This setup provides enhanced efficiency and improved safety. According to industry reports, concentric cable can reduce energy losses by up to 30% compared to traditional cables.

Applications of concentric cable are diverse. They are commonly used in urban power distribution and street lighting systems. The reduced electromagnetic interference is a significant benefit. However, installation can be challenging. Proper techniques are crucial to avoid issues like insulation failure.

Attention to detail is vital. Ensure that the installation area is free from moisture. Any exposure can lead to long-term damage. Also, remember to follow safety guidelines. Missteps can result in costly mistakes. Inexperienced crews may overlook these aspects, leading to unnecessary complications.

| Dimension | Value | Applications |

|---|---|---|

| Conductor Size (mm²) | 10 | Residential wiring |

| Insulation Type | XLPE | Underground applications |

| Nominal Voltage (kV) | 1.2 | Industrial installations |

| Cable Length (m) | 500 | Utility poles |

| Operating Temperature (°C) | 90 | High-temperature environments |

| Installation Method | Direct burial | Subsurface installations |

Installing concentric cable requires careful planning and the right tools. To start, you'll need a cable cutter. This tool will help you make clean cuts. A good pair of wire strippers is also essential. These will ensure you properly prepare the ends of the wires. Another important item is a cable crimping tool. It’s essential for connecting connectors securely.

Proper materials are just as important. Ensure you have enough cable. Measure twice, cut once—this phrase rings true. The connectors should match the cable size. Not having the right ones can lead to poor connections. Remember to have insulating tape handy. This tape will protect exposed wires from accidental contact.

Testing your installation after completion is critical. A voltage tester can help ensure safety. Make sure all connections are secure. If something feels off, it’s worth taking a step back. Sometimes, you think you’ve done it right, but a little oversight can cause issues. Reflecting on your work can lead to better results in future projects.

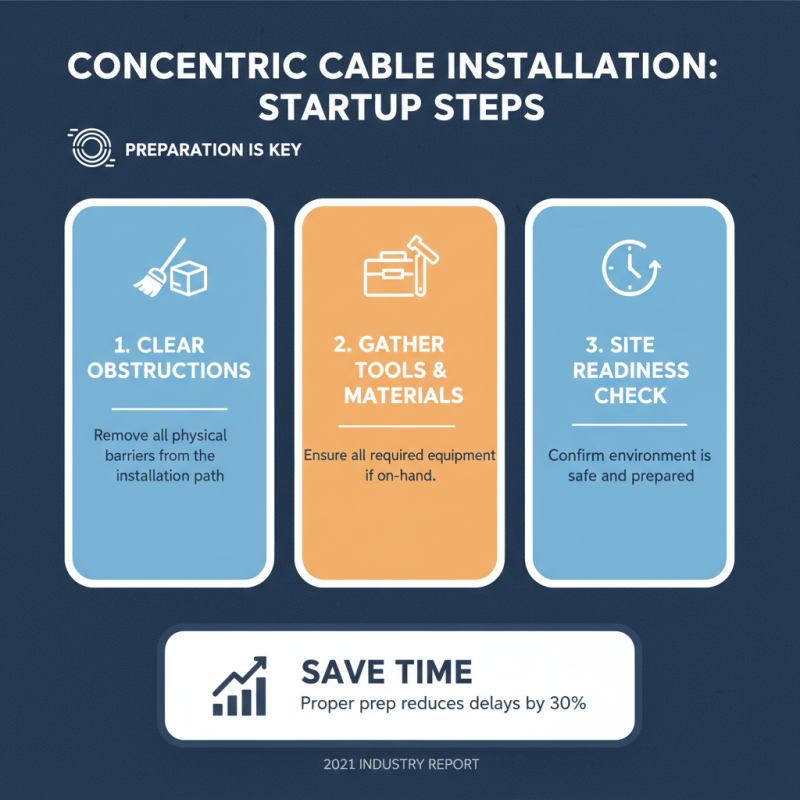

Installing concentric cable can seem challenging, but breaking it down into manageable steps helps. Start by preparing the installation site. Clear any obstructions. Ensure you have the right tools and materials on hand. A 2021 industry report highlighted that improper preparation can lead to installation delays up to 30%. Time spent on setup can prevent frustrating inefficiencies later.

Next, be mindful of cable termination. Proper termination ensures a reliable connection. Missteps in this phase might lead to increased signal loss. According to a recent study, approximately 15% of installation failures arise from poor cable terminations. Taking time to follow manufacturer guidelines is crucial. Use the correct tools for stripping and crimping to secure connections. Clear labels can help during the troubleshooting phases.

Once everything is terminated, proceed with the pulling of the cable. Avoid excessive tension to prevent damage. It's common to overlook this detail, leading to compromised performance. Always measure the distance before pulling. A 2022 study indicated that nearly 20% of installation issues result from improper cable handling. Flexibility and attention to detail during this process lead to better results. Each step requires focus.

When installing concentric cable, safety is a top priority. Always wear appropriate personal protective equipment, including gloves and safety goggles. Make sure the work area is clear of hazards. Familiarize yourself with the tools and equipment you will use. Proper preparation can prevent accidents.

Before beginning the installation, inspect the cable and connections thoroughly. Look for any signs of damage. Damaged cables could lead to failures or hazards later. It's crucial to maintain safe handling practices to avoid injuries.

Tips: Use a cable drum to manage the concentric cable effectively. This prevents tangling and damage during installation. Ensure that the cable is laid out flat without twists. Mistakes can occur here, so double-check each step.

By being mindful of these precautions, your installation process will be safer and more efficient. Remember, reflect on your steps as you work. Attention to detail is vital. Take your time and don’t rush through the installation.

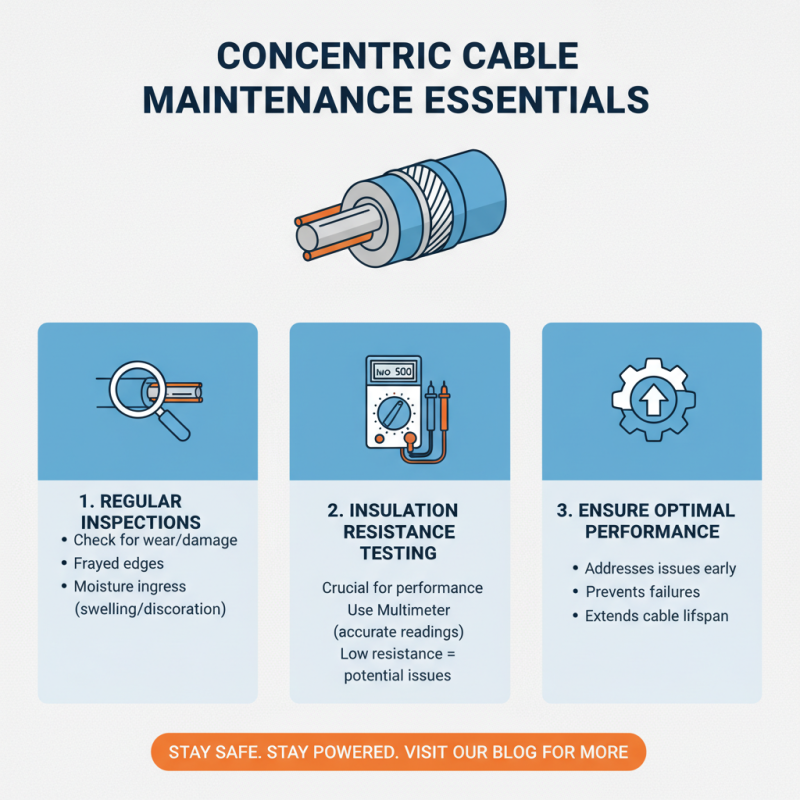

Testing and maintaining installed concentric cable systems are essential steps for any project. Regular inspections help ensure optimal performance. Look for signs of wear or damage. This includes frayed edges or moisture ingress. Testing the insulation resistance is crucial. Use a multimeter for accurate readings. A resistance lower than acceptable levels could indicate issues.

Routine maintenance can prevent bigger problems. Schedule periodic checks to monitor system integrity. Documentation is vital—keep records of all tests performed. This helps identify patterns over time. Note any fluctuations in performance. If you observe any, dig deeper to investigate causes. Sometimes, degradation might not be visible.

Always prioritize safety during maintenance. Disconnect the power supply before starting any work. Relying on a visual inspection alone can be misleading. Some failures are hidden. Testing with appropriate tools is key. Your focus should be on reliability and longevity. Maintain a proactive approach to keep systems running smoothly.